AUTOMATIC SETTING

Through a P.I.D. potentiometric pyrometer linked to a Pt.PtRh thermocouple set inside the

muffle and protected by a ceramic covering.

GENERAL SPECIFICATIONS

The furnaces belonging to this group are built starting from the floor and consist mainly of

two parts:

-- The external muffle is separate from the steelwork

-- The external steelwork

OPTIONS

-- Daily or weekly timer

-- Temperature-time setting unit

-- Automatic compensation for ageing of the resistors

THERMOELECTRIC EQUIPMENT

It consists of silite rods used with low surface load for lower ageing and improved constant

temperature of the muffle. The silite rods are laid transversally to the chamber, on the

furnace crown under the hearth. The incandescent part corresponds to the width of the

muffle. The terminal metal ends protruding from the two sides of the furnace are connected

through special clamps devised to prevent overheating. A natural draught cools the

connections. The number of silite rods used to make a thermoelectric equipment vary

according to the type of furnace and to the maximum temperature achievable.

Used to check machine load and the wearing away of the rods.

Silicon carbide resistor furnaces are devised to carry out high temperature treatments in

perfect safety. Such safety features are the result of great attention to the following:

- Accurate choice of the materials used

- Wide and progressive insulation

- Separation of the muffle from the external steelwork

- The use of low surface load resistors

DOOR

Quick sliding opening device through a lever set by the furnace. Upon opening the door, a

microchip disconnects the heating elements.

TREATMENT CHAMBER

It is made of refractory silica alumina with heat and thermal shock resistant silicon

carbide hearth.

THERMAL INSULATION

With separate refractories characterized by separate thermal conductivity.

SPECIAL FUNCTIONS

Screened muffle when the substances treated may damage the silite rods. The top temperature

is dropped by 100 °C during the screened function. INERT OR REDUCING ATMOSPHERES.

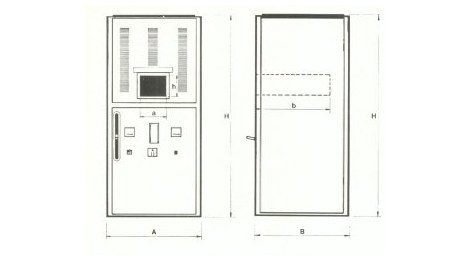

| Model | Dimensions mm | Weight | Power | Max temperature °C | Tension | ||||||

| a | h | b | A | H | B | Mono. | Tri. | ||||

| SF 4 | 150 | 100 | 250 | 570 | 1620 | 810 | 150 | 4 | 1400 | * | * |

| SF 6 | 180 | 120 | 300 | 570 | 1620 | 810 | 200 | 6,5 | 1400 | * | * |

| SF 10 | 200 | 150 | 350 | 700 | 1620 | 860 | 400 | 8,5 | 1400 | * | |

| SF 16 | 200 | 180 | 400 | 910 | 1960 | 1110 | 600 | 14 | 1400 | * | |

| SF 25 | 250 | 200 | 500 | 910 | 1960 | 1110 | 800 | 16 | 1400 | * | |

| SF 40 | 400 | 400 | 600 | 1110 | 1960 | 1210 | 1000 | 38 | 1400 | * | |